Digital Textile Printing Market Size, Segments, Share and Companies (2025-34)

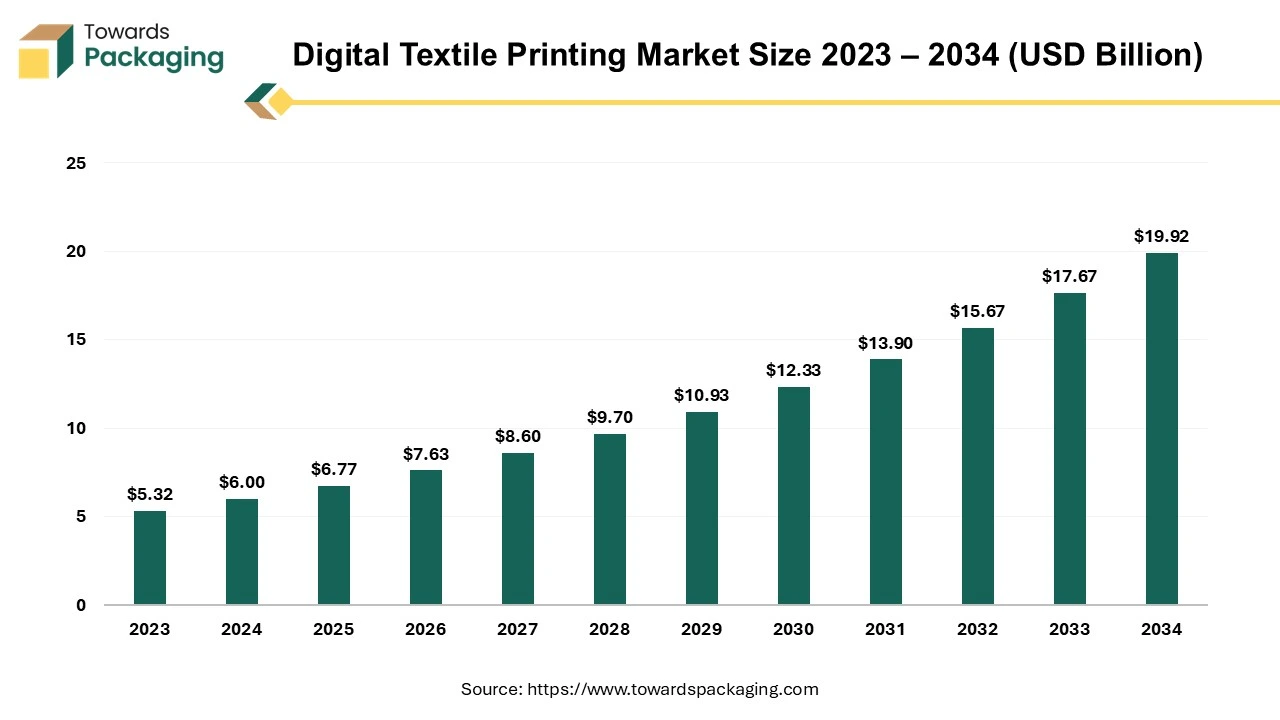

According to Towards Packaging consultants, the global digital textile printing market is projected to reach approximately USD 19.92 billion by 2034, increasing from USD 6.77 billion in 2025, at a CAGR of 12.75% during the forecast period 2025 to 2034.

Ottawa, Oct. 27, 2025 (GLOBE NEWSWIRE) -- The global digital textile printing market stood at USD 6.77 billion in 2025 and is projected to reach USD 19.92 billion by 2034, according to a study published by Towards Packaging, a sister firm of Precedence Research. Key trends driving this market include the rise of mass customization, a shift toward high-speed and automated printing solutions, and a strong emphasis on eco-friendly practices, such as water-saving technologies and the use of sustainable inks.

What is Digital Textile Printing?

Digital textile printing is a procedure that utilizes inkjet technology to apply colorants directly onto fabric, alike to a home inkjet printer but with customized inks and even large-format machines. It allows the creation of intricate designs, also ranging from small-run custom pieces to large-scale manufacturing for banners and flags. It is usually regarded as a more sustainable alternative to conventional screen printing. Significance lies in its ability to offer production efficiency, greater creative freedom, and even environmental benefits via customization, speed, and reduced waste.

Request a Custom Case Study and Research Report Built Around Your Goals: sales@towardspackaging.com

What are the Latest Trends in the Digital Textile Printing Market?

Growth of High-Speed Single-Pass Printers for Mass Production

Single-pass printers use multiple print heads positioned across the full width of the fabric to produce images in a single pass, enabling significantly faster production compared to traditional multi-pass printers that move the print head back and forth. Some machines can achieve speeds of up to 40 linear meters per minute. This technology supports the printing of complex designs, rapid style changes, and large-volume production on demand, meeting the needs of the fast-paced fashion industry and enabling efficient, on-demand manufacturing.

Surge in Eco-Friendly Inks

Digital textile printing is inherently more sustainable, using significantly less water and fewer chemicals than conventional dyeing processes. The adoption of eco-friendly inks further reduces chemical waste and environmental pollution. Companies embracing these inks gain a competitive advantage by aligning with environmental values and meeting growing consumer demand for sustainable practices.

Increased Demand for Customization and Short-Run Production

Modern consumers, especially younger generations, increasingly seek personalized and fashionable products that reflect their individual style. Digital textile printing empowers brands to offer high levels of customization, from custom graphics on apparel to unique patterns on home décor. It also enables quicker production cycles and faster turnaround times, allowing brands to respond swiftly to changing fashion trends and maintain a competitive edge.

What Potentiates the Growth of the Digital Textile Printing Market?

Increasing consumer demand for customized products fuels market expansion. Digital printing allows for cost-effective and even on-demand production of unique items without high setup expenses, enabling manufacturers to offer a wide range of personalized designs for home décor, fashion, and more. The ability to print on demand allows businesses to respond quick to changing trends and customer choices, decreasing the risk of overstocking or understocking.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5447

Limitations & Challenges in the Digital Textile Printing Market

The major limitations and challenges in the market are the high initial investment required for equipment, specialized inks, and even limited fabric compatibility. Other challenges include maintaining consistent color across different runs and fabrics, reduced manufacturing speeds compared to conventional methods, the need for skilled operators to manage complex technology, and issues with ink durability and color fastness, particularly on certain natural fibers.

Regional Analysis

Who is the Leader in the Digital Textile Printing Market?

Asia Pacific dominated the market by holding the largest share in 2024. This is mainly due to its large production base, the high demand for customized products in the rapidly growing textile and e-commerce sectors, and government initiatives that support the transition to more sustainable and efficient digital printing. Numerous governments in the region are encouraging the textile sector and influencing the adoption of more sustainable production processes, such as digital printing. The growth of fast fashion trends has increased the demand for quick turnaround times and the ability to manufacture smaller runs of diverse designs, which align perfectly with the capabilities of digital printing.

China Market Trends

China produces over 50% of the world's textiles, creating a significant demand for digital printing to support faster and more versatile production processes. As a result, the country is both a major user and exporter of digital printing equipment. Additionally, the global demand for personalized apparel and home textiles is a key growth driver. Digital printing enables the creation of unique, on-demand designs, a trend further fueled by the rise of global e-commerce platforms.

Japan Market Trends

Digital textile printing aligns with Japan’s growing emphasis on eco-friendly practices, as it reduces waste and supports the use of water-based inks, making it a more sustainable alternative to traditional methods. Japan's high urbanization rate, advanced infrastructure, and strong commitment to research and development create an ideal environment for the market to grow and innovate.

How is the Opportunistic Rise of North America in the Digital Textile Printing Market?

North America is expected to experience the fastest growth in the market during the forecast period. Consumers in the region, especially millennials, are increasingly seeking unique and personalized products, from apparel to home décor. Digital printing supports this trend by enabling on-demand production of customized and small-batch items, reducing the financial risks associated with excess inventory. Additionally, supply chain disruptions and government initiatives promoting domestic manufacturing are encouraging brands to bring textile production closer to home. The flexibility and speed of digital printing make it an ideal solution for localized manufacturing strategies.

U.S. Market Trends

The U.S. digital textile printing market is experiencing significant growth, driven by rising demand for sustainability, customization, and flexible production models such as direct-to-consumer (DTC) businesses. Innovations in inkjet technology, offering faster speeds and improved durability, are narrowing the gap between traditional and digital printing methods, while creating new opportunities for short-run, personalized production.

Canada Market Trends

Canadian consumers are increasingly seeking personalized clothing and home textiles featuring unique logos, designs, and messages. Digital textile printing supports this demand through easy customization and efficient short-run production. Canada’s mature e-commerce ecosystem and the rise of fast fashion support on-demand printing models, which rely on the flexibility and speed of digital technology. This enables brands to respond to emerging trends with small-batch, just-in-time manufacturing quickly.

More Insights of Towards Packaging:

- 3D-Printed Stickers & Labels Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA) and Companies - https://www.towardspackaging.com/insights/3d-printed-stickers-and-labels-market-sizing

- Print-receptive PE films Market Key Trends, Disruptions and Strategic Imperatives - https://www.towardspackaging.com/insights/print-receptive-pe-films-market-sizing

- Packaging Tape Printing Market Size, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/packaging-tape-printing-market-sizing

- North America Packaging Tape Printing Market Leadership in 2025 Reinforced by 3M, Shurtape, and UPM New Product Launches - https://www.towardspackaging.com/insights/north-america-packaging-tape-printing-market-sizing

- Folding Carton in Healthcare Market Insights for 2025 Indicate Offset Printing Leadership and Digital Surge - https://www.towardspackaging.com/insights/folding-carton-in-healthcare-market-sizing

- Commercial Printing Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/commercial-printing-market-sizing

- Low-Carbon Footprint Packaging Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/low-carbon-footprint-packaging-market-sizing

- 3D Printed Packaging Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/3d-printed-packaging-market-sizing

- Offset Printing Market 2025 Research Shows High Growth at 14.13% CAGR to 2034 - https://www.towardspackaging.com/insights/offset-printing-market-sizing

- Cardboard Boxes Market to Soar with Fit-to-Product & Digital Printing Innovations - https://www.towardspackaging.com/insights/cardboard-boxes-market-sizing

- Thermal Printing Market 2025 Outlook: Barcode Printers & Direct Thermal Tech to Dominate USD 79.33 Billion Sector - https://www.towardspackaging.com/insights/thermal-printing-market-sizing

- Tablet Inspection and Printing System Market Investment Opportunities & Competitive Benchmarking - https://www.towardspackaging.com/insights/tablet-inspection-and-printing-system-market-sizing

- Security Printing Services Market Growth, Trends, and Technological Advancements (2025-2034) - https://www.towardspackaging.com/insights/security-printing-services-market-sizing

- Printed Signage Market Trends, Drivers, and Competitive Landscape (2025-2034) - https://www.towardspackaging.com/insights/printed-signage-market-sizing

- Packaging Printing Market Size, Key Trends, Technologies, and Regional Dynamics (2025-2034) - https://www.towardspackaging.com/insights/packaging-printing-market-sizing

- Digital Printing Packaging Market Drives at 9.8% CAGR (2025-34) - https://www.towardspackaging.com/insights/digital-printing-packaging-market-size

Segment Outlook

Printing Process Insights

The direct-to-fabric (roll-to-roll printing) segment dominated the digital textile printing market in 2024. This is due to its ability to manage high-volume production, its versatility across numerous fabric types, and the increasing need for customization in fashion as well as home décor. It eliminates the costly and time-consuming setup processes associated with traditional methods like screen printing, allowing for faster turnaround times and lower production expenses for short runs and customized orders.

Material Operation Insights

The single pass segment dominated the market with a major revenue share in 2024. This is due to its high speed, which allows faster turnaround times and even efficient mass production, together with high print quality achieved via multiple printheads working simultaneously. The increasing demand for customized products and technological advancements in inks and printers drives the expansion. Additionally, there is a push for more sustainable and eco-friendly printing procedures, for which single-pass technology is better equipped to manage large-scale production. Despite its speed, the technology delivers excellent print quality, making it suitable for mass production while still providing the precision required for high-resolution printing.

Material Insights

The cotton segment dominated the digital textile printing market in 2024. This is due to its excellent moisture absorption, softness, durability, and printability make it ideal for sportswear, fashion, and home décor items. Meanwhile, advances in digital printing technology have increased its appeal, while the use of pigment-driven inks simplifies the printing process by reducing pre- and post-treatment needs.

Cotton is highly receptive to a number of digital printing inks, such as reactive and pigment-based inks, which produce vibrant and durable designs. The rising need for personalized fashion and even custom-designed home goods fuels the demand for digitally printed cotton fabrics. The advancement of new ink formulations and even more efficient printing technologies has driven digital printing on cotton faster and more reliable.

Ink Type Insights

The sublimation segment dominated the market in 2024. This is due to its compatibility with polyester fabrics, which are broadly used in fashion, sportswear, and home décor. This supremacy is also driven by its ability to manufacture vibrant, durable, and even long-lasting prints with excellent wash resistance, meanwhile also being an eco-friendly process that eliminates water use and waste. Sublimation manufactures vibrant, saturated colors that become a permanent part of the fabric, resulting in highly durable, long-lasting prints resistant to fading and washing.

Application Insights

The clothing/apparel segment dominated the digital textile printing market in 2024. This is due to the need for fast fashion, on-demand manufacturing, and mass customization. Consumers increasingly need unique clothing that reflects their personal style. Digital printing makes it easy to manufacture customized items, like T-shirts with personal designs, on demand without the requirement for large inventories. Digital printing is usually more sustainable than conventional methods because it utilizes less water, energy, and even chemicals, and it generates less waste. This aligns with the growing consumer and industry goals for more eco-friendly production.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Recent Breakthroughs in the Market

- On October 16, 2025, Kornit Digital Ltd. announced that it is ready to join over 40 customers and partners at PRINTING United Expo 2025 in Orlando, highlighting innovators reshaping digital apparel and textile production. From October 22–24 at booth 5270, Kornit is set to host discussions on customer success stories and how it's enabling growth and agility in on-demand manufacturing. Attendees can connect directly with users who’ve successfully transformed their operations through digital textile solutions.

- In February 2025, Mimaki Engineering Co., Ltd. announced the launch of the "Tx330-1800" and "Tx330-1800B" direct-to-textile inkjet printers for the apparel and textile market, offering high image quality with minimal water usage. The Tx330-1800 makes its global debut at JAPAN SHOP in Tokyo on March 4, 2025, showcasing a versatile, waterless digital printing solution.

Key Players Operating in the Market

- Seiko Epson Corporation

- Mimaki Engineering

- Kornit Digital

- Electronics for Imaging

- Roland DG Corporation

- Sawgrass Technologies Inc

- Spgprints B. V.

- Atexco

- Durst Phototechnik

- Konica Minolta

- Ricoh

- Colorjet

- Brother Industries

- Agfa Graphics

- Hollanders Printing Solutions

Segments Covered in the Report

By Printing Process

- Direct to Fabric (Roll to Roll Printing)

- Direct to Garment (DTG)

By Material Operation

- Single Pass

- Multi Pass

By Material

- Cotton

- Silk

- Polyester

- Others

By Ink Type

- Sublimation

- Pigment

- Reactive

- Acid

- Others

By Application

- Clothing/Apparel

- Home Décor

- Soft Signage

- Industrial

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Malaysia

- Philippines

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of the Middle East & Africa

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5447

Request a Custom Case Study and Research Report Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

-

Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Healthcare | Towards Automotive | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

Towards Packaging Releases Its Latest Insight - Check It Out:

- Asia Pacific Food Packaging Market Growth, Key Segments, and Regional Dynamics with Manufacturers and Suppliers Data

- Biaxially Oriented Polyethylene Terephthalate (BOPET) Films Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis

- Europe Pharmaceutical Packaging Market Growth, Key Segments, and Regional Dynamics with Manufacturers and Suppliers Data

- Tetrahedron Carton Market Size, Share, Trends, Segments, and Regional Insights (NA, EU, APAC, LA, MEA)

- Europe Flexible Packaging Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- North America Pharmaceutical Packaging Market Growth, Key Segments, and Regional Dynamics with Manufacturers and Suppliers Data

- Single-Use Plastic Water Bottles Market Growth, Key Segments, and Regional Dynamics with Manufacturers and Suppliers Data

- Cement Packaging Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Dairy Product Packaging Market Size, Segments, Share and Companies (2025-34)

- Stick Packaging Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Europe Glass Prefilled Syringes And Glass Vials Packaging Equipment Market Growth, Key Segments, and Suppliers Data

- North America Automotive Thermoformed Plastic Parts Packaging Market Growth, Key Segments and Regional Dynamics

- Baby Food Packaging Market Size, Share, Trends, Segments, and Regional Insights (NA, EU, APAC, LA, MEA)

- Pharmaceutical Plastic Packaging Market Growth, Key Segments, and Regional Dynamics with Manufacturers and Suppliers Data

-

North America Post-Consumer Recycled Plastics Food Packaging Market Growth, Key Segments, and Suppliers Data

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.